OFFSHORE STRUCTURES, OIL PLATFORMS, RIGS & VESSELS

Underwater Inspection, Maintenance & Repairs of Offshore structures

Offshore structures such as oil and gas platforms, subsea pipelines, wind farms, and marine terminals operate in some of the harshest environments on earth. Constant exposure to high hydrostatic pressure and accidental impacts gradually compromises their integrity and safety. Over time, these conditions can cause coating breakdown, corrosion and even structural damage that threatens safe operations. To mitigate these risks, Underwater Inspection, Maintenance, and Repair (IMR) activities are carried out using divers, Remotely Operated Vehicles (ROVs), and specialized equipment. Inspections provide critical data through visual surveys, CCTV footage, and advanced Non-Destructive Testing (NDT) techniques such as Ultrasonic Testing (UT) and Cathodic Protection (CP) surveys, helping to detect early-stage defects.

Pre-engineering surveys.

Pre-engineering surveys are the first and most critical step in any offshore, marine, or industrial project, as they establish the foundation upon which all subsequent design and engineering work is based.In the offshore sector, surveys typically include hydrographic and bathymetric mapping to determine seabed profiles, geotechnical investigations such as borehole sampling and soil strength testing for foundation design, and geophysical studies using sonar and sub-bottom profilers to detect buried objects, voids, or rock layers. Environmental and oceanographic data—including currents, tides, waves, wind patterns, and marine ecology—are also gathered to predict long-term operational impacts. In industrial and onshore projects, pre-engineering surveys cover topographical mapping, soil testing, and utility surveys, which provide insights into load-bearing capacities, drainage, and existing infrastructure.

UWILDsurveys.

UWILD (Underwater Inspection in Lieu of Dry Docking) is a highly specialized inspection regime approved by major classification societies such as ABS, DNV, LR, BV, and IRS. It is designed to replace or postpone the need for traditional dry-docking by carrying out all required underwater surveys while the vessel or offshore unit remains afloat and in service. This method has become a standard practice for ships, tankers, drillships, semi-submersibles, FPSOs, FSOs, and other floating assets where dry-docking may be logistically challenging, costly, or result in extended downtime.The scope of a UWILD survey typically includes a full external hull examination, inspection of weld seams and plating, verification of protective coatings, and assessment of cathodic protection systems. Critical components such as propellers, thrusters, rudders, sea chests, sea valves, anodes, and mooring systems are carefully examined to detect corrosion, cracks, erosion, cavitation, or mechanical wear.

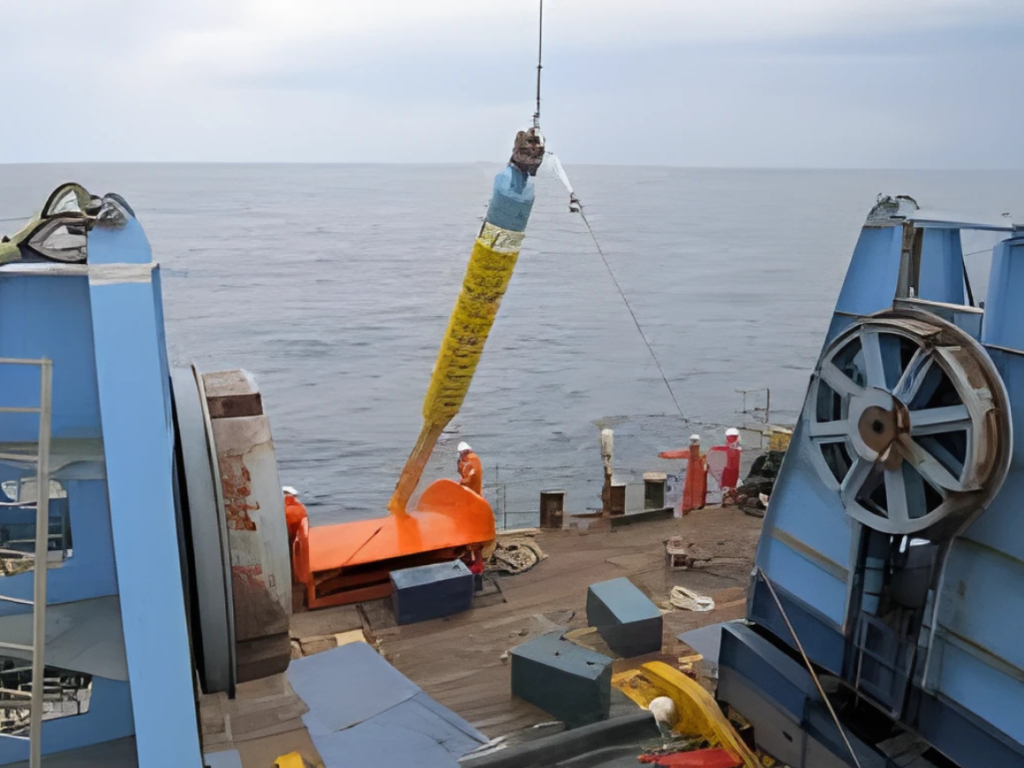

Diving Support for Pipe laying, Diffuser & Umbilical Installation.

Pipe laying, diffuser installation, and subsea umbilical deployment are some of the most complex and mission-critical activities in offshore construction projects. These operations demand precision engineering, safe handling of heavy subsea equipment, and strict compliance with international standards due to the high-risk marine environment in which they are executed. The success of such projects depends on maintaining exact seabed alignment, robust mechanical and welded connections, and thorough integrity verification throughout the installation process.While Remotely Operated Vehicles (ROVs) and automated systems have transformed subsea construction, there remain numerous tasks that require skilled diver intervention. This is where diving support becomes indispensable. Professional commercial divers, equipped with advanced breathing systems and subsea tools, are deployed from Diving Support Vessels (DSVs) or work barges.

Underwater NDT Inspection using MPI, CP and UT devices.

Non-Destructive Testing (NDT) plays a vital role in the integrity management of subsea and offshore assets because it allows engineers to detect and quantify defects without impairing the functionality of the structure itself. Offshore platforms, subsea pipelines and mooring systems are continuously subjected to saltwater corrosion, high hydrostatic pressure, marine growth, hydrodynamic loading, and operational stresses. These harsh conditions lead to material degradation such as pitting corrosion, wall thinning, weld cracking, coating breakdown, and fatigue failures. Without proper inspection, such issues may progress unnoticed, potentially resulting in leaks, structural collapses, or costly shutdowns.Underwater NDT inspection provides accurate, real-time data on the condition of submerged assets, ensuring early detection of damage and supporting timely maintenance or repair. Professional divers and ROVs (Remotely Operated Vehicles), equipped with advanced NDT instruments, conduct surveys even in deepwater or low-visibility conditions.

Underwater Inspection using Underwater Still Photography and Video Photography (CCTV).

Underwater inspection through still photography and video (CCTV) is one of the most practical and widely accepted techniques for documenting the condition and integrity of subsea assets. It provides operators, engineers, and classification societies with clear visual evidence of asset health, enabling them to make informed decisions about maintenance and repairs.High-resolution cameras are deployed either by commercial divers or Remotely Operated Vehicles (ROVs), depending on water depth, visibility, and project requirements. These cameras are equipped with powerful underwater lighting systems to overcome turbidity and low natural light conditions. The captured imagery includes both still photographs for detailed analysis and continuous video feeds for real-time monitoring and class-approved documentation.

Installation & Replacement of Jacket, Pipelines, Risers, Clamps, Conductors and Anodes.

Offshore assets such as oil & gas platforms, subsea pipelines, risers, conductors, clamps, and production systems operate under some of the harshest conditions in the world’s oceans. Constant exposure to seawater corrosion, hydrodynamic forces, high operating pressures, and cyclic fatigue loading gradually weakens both structural components and protective systems. Over time, this results in coating breakdown, anode depletion, wall thinning, weld cracking, and mechanical damage, all of which require either the installation of new systems or the replacement and strengthening of existing ones to maintain operational integrity.These complex tasks are carried out using a combination of diver-assisted methods, Remotely Operated Vehicles (ROVs), and specialized offshore construction equipment to ensure that work is conducted safely, precisely, and in line with international standards.

Installation, Preservation & Maintenance of Offshore Oil Terminals, S.B.M and S.P.M.

Offshore oil terminals are among the most critical components of the global energy supply chain, serving as transfer hubs for crude oil and refined petroleum products between oceangoing tankers, subsea pipelines, and onshore storage facilities. In locations where building fixed marine terminals is impractical due to deepwater conditions, limited coastal infrastructure, or environmental sensitivities, floating solutions such as Single Buoy Mooring (SBM) and Single Point Mooring (SPM) systems are widely deployed. These terminals allow very large crude carriers (VLCCs) and other tankers to safely moor offshore and transfer cargo efficiently, even in challenging marine environments.SBM and SPM systems consist of buoys anchored to the seabed with chains or mooring lines, connected to subsea pipelines and risers that carry crude oil to and from onshore facilities. Their swiveling heads and flexible hose systems enable tankers to remain securely moored while rotating freely with prevailing winds, currents, and tides, thus reducing stress on both the vessel and the terminal.

Complete flushing of S.B.M. and S.P.M. systems.

Single Buoy Mooring (SBM) and Single Point Mooring (SPM) systems serve as lifelines for offshore crude oil and petroleum product transfer, connecting large tankers to subsea pipelines and onshore storage facilities. These terminals operate continuously in harsh marine environments and handle high volumes of hydrocarbons under pressure. Over time, the internal transfer systems—pipelines, risers, manifolds, swivel stacks, and flexible hoses—accumulate sediments, wax deposits, scale, rust particles, marine debris, and stagnant fluids. If left unaddressed, these contaminants can cause flow restrictions, pressure losses, product contamination, accelerated corrosion, and even catastrophic leaks.Complete flushing of SBM/SPM systems is therefore a critical maintenance activity that restores cleanliness, operational integrity, and flow efficiency. The process involves high-capacity pumping systems, pigging units, filtration equipment, and chemical treatments designed to remove all contaminants from the internal network of hoses and pipelines.

Underwater cleaning of marine growth using hydro pressure jets.

Marine growth—ranging from soft organisms such as algae, slime, and hydroids to hard fouling species like barnacles and calcareous deposits—is a persistent challenge for all submerged assets. Offshore structures, SBM/SPM systems, and port installations are particularly vulnerable. The accumulation of this growth not only alters the hydrodynamic profile of these assets but also leads to increased drag and fuel consumption for vessels, blockage of cooling water intakes, accelerated corrosion under deposits, degradation of protective coatings, and premature consumption of cathodic protection (anodes). If ignored, biofouling significantly reduces efficiency, raises operational costs, and can even compromise asset safety.The process is carried out by commercial divers or Remotely Operated Vehicles (ROVs) using high-pressure water jetting systems that can be adjusted to suit the type of fouling and the sensitivity of the surface being cleaned.

Underwater inspection, maintenance & repairs of ships and all types of sea going vessels.

Ships and sea-going vessels—including tankers, container ships, bulk carriers, naval vessels, offshore supply ships, and cruise liners—are exposed to continuous stresses from the marine environment. Seawater causes corrosion and pitting, marine organisms form thick biofouling layers on hulls and intakes, and constant hydrodynamic forces lead to structural fatigue, coating breakdown, and mechanical wear. Left unchecked, these issues can compromise seaworthiness, fuel efficiency, and regulatory compliance.To address these challenges without disrupting operations or incurring expensive dry-docking costs, operators rely on Underwater Inspection, Maintenance, and Repair (IMR) services performed while vessels remain afloat. These services are carried out by class-approved commercial divers and, in deeper or high-risk waters, Remotely Operated Vehicles (ROVs).

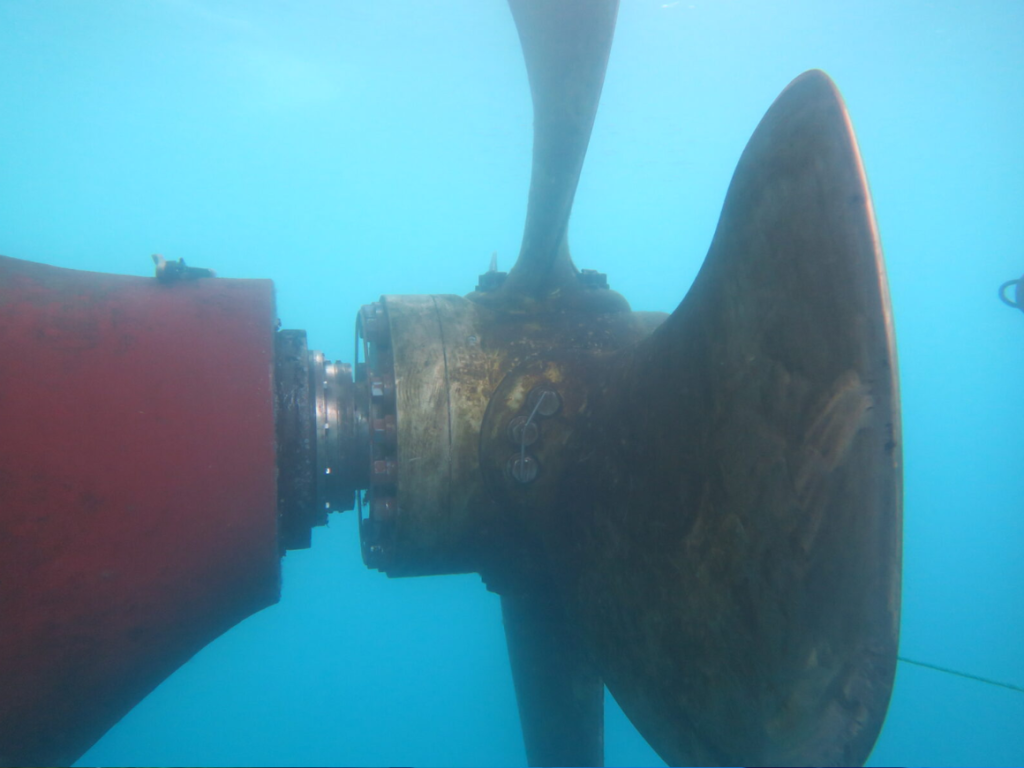

Hull & Propeller cleaning & polishing.

The hull and propeller are among the most vital components of a vessel, directly influencing fuel efficiency, propulsion power, and overall performance. Continuous exposure to seawater leads to the accumulation of marine growth such as algae, barnacles, and calcareous deposits, which increase hydrodynamic drag, accelerate corrosion, and reduce the effectiveness of protective coatings and cathodic protection systems. Even light fouling can raise fuel consumption by 10–20%, while a heavily fouled propeller can reduce efficiency by up to 30%, resulting in higher operating costs and increased emissions. The hull is cleaned of fouling to restore smoothness, while the propeller undergoes a multi-stage polishing process that achieves a mirror-like finish with a surface roughness of less than 0.8 μm, minimizing cavitation and restoring optimal thrust. These services improve vessel speed and maneuverability, reduce fuel consumption and greenhouse gas emissions, extend the life of coatings and machinery, and minimize the frequency of dry-docking.

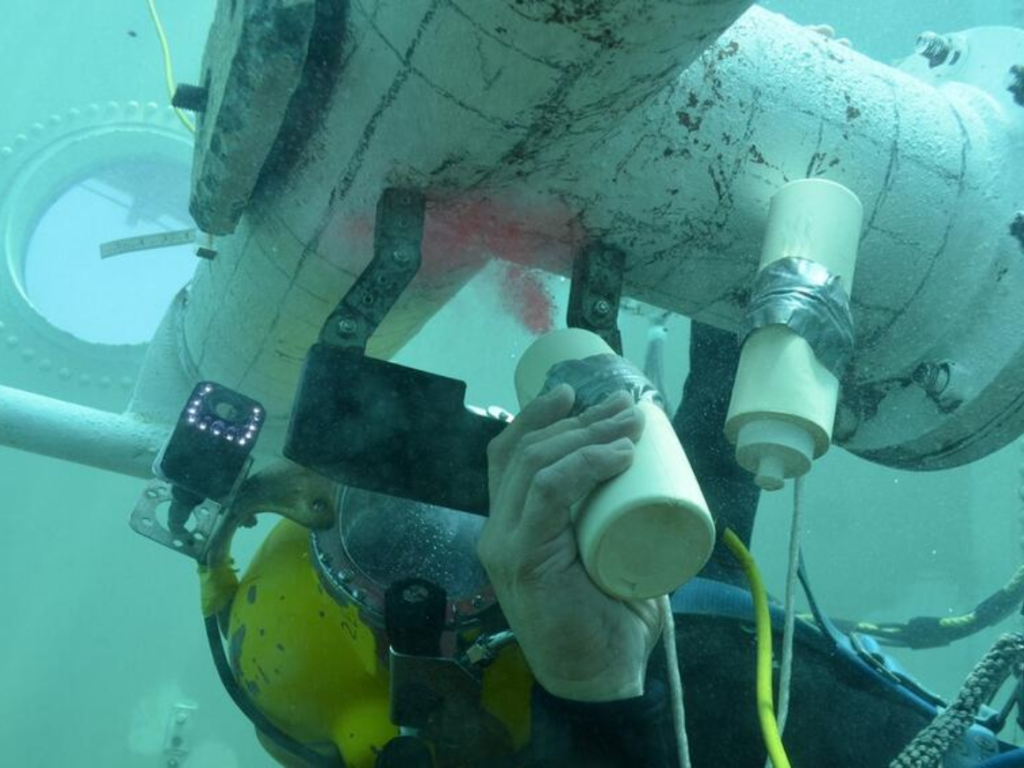

Sealing of stern glands.

The stern gland, also known as the shaft seal or propeller shaft packing, is one of the most critical watertight components in a vessel’s propulsion system. Positioned where the propeller shaft passes through the hull into the sea, its primary role is twofold: to prevent seawater from entering the vessel and to retain lubrication oil within the stern tube bearings. This ensures that the bearings are properly lubricated, the shaft runs smoothly, and the propulsion system remains reliable.However, due to the constant rotation of the shaft, vibration, misalignment, exposure to corrosive seawater, and ingress of debris or sand particles, stern gland seals inevitably degrade over time. This can lead to serious operational problems such as oil leakage into the sea (environmental hazard), seawater ingress into the stern tube (bearing contamination), increased wear of the shaft surface, overheating of bearings, and ultimately propulsion failure.

Blanking of sea suction grating.

Sea suctions (or sea chests) are vital intake points located along a vessel’s hull that supply seawater to critical systems such as main engine and auxiliary cooling, ballast operations, firefighting systems, HVAC systems, and other onboard machinery. To prevent the entry of large debris, marine organisms, or foreign objects, these openings are fitted with protective gratings. However, during scheduled maintenance or in emergency situations, it often becomes necessary to blank (seal off) these sea suction gratings.Blanking of sea suctions is the process of temporarily isolating the intake by fitting an external or internal blanking device over the grating. This allows internal valves, piping, filters, pumps, or other machinery connected to the system to be safely inspected, repaired, overhauled, or replaced without the risk of uncontrolled seawater ingress.

Underwater repairs to any Structural Damage etc and many more….

Marine and offshore structures—such as ships, subsea pipelines, offshore platforms, FPSOs, and port facilities—are exposed to continuous environmental stresses including waves, currents, corrosion, and accidental impacts (from vessels, dropped objects, or anchors). These conditions can lead to structural damage, cracks, dents, coating failures, and component failures below the waterline.underwater repair services enable restoration of these critical assets while afloat or in operation, eliminating the need for costly and time-consuming dry-docking. Specialized divers, ROVs, and advanced subsea welding, cutting, and repair technologies are employed to ensure safe, class-approved, and long-lasting solutions.