UNDERWATER DIVING SERVICES FOR HYDRO POWER & IRRIGATION PROJECTS

Repairs & cleaning of Gate grooves, Stop log gate, Penstock gate, etc. on Dam & Hydro Power plants.

In hydro power plants and dam structures, hydro-mechanical gates are the backbone of safe water regulation and power generation. These include spillway gates, stop log gates, penstock intake gates, and associated gate grooves, all of which are exposed to continuous hydrostatic pressure, abrasive silt, debris impact, cavitation, and corrosion. Any compromise in these components can lead to water leakage, uncontrolled discharge, reduced turbine efficiency, safety hazards, or even catastrophic failures.Hence, underwater inspection, repair, and cleaning services are vital to maintain reliable operation and extend the service life of critical hydraulic infrastructure.

Flood gate recovery and shutter assembling on Dam & Hydro Power Plants.

Flood gate recovery and shutter assembling are critical maintenance and repair activities in dams and hydro power plants, ensuring safe water regulation and uninterrupted power generation. Over time, flood gates may suffer from corrosion, jamming, deformation, or even dislodgement due to high water pressure, silt abrasion, and debris impact. Recovery involves detailed underwater inspections by divers or ROVs, cleaning of grooves and seating areas, removal of silt and debris, and the use of heavy-duty cranes, winches, or hydraulic jacks to lift, realign, and reinstall the gates. Damaged components such as hinges, trunnions, or seals are repaired or replaced, and protective coatings are reapplied to prevent further deterioration. Similarly, shutter assembling—whether for stop logs, emergency gates, or intake shutters—requires precision cleaning of grooves, lowering and alignment of shutter panels, installation of seals, and hydrostatic testing to confirm watertightness.

Underwater Still Photography & Video Photography (CCTV).

Underwater still photography and video photography (CCTV) are widely used techniques for documenting the condition of subsea and hydraulic structures without interrupting operations. High-resolution cameras operated by commercial divers or Remotely Operated Vehicles (ROVs) capture detailed images and continuous video footage of submerged components such as hulls, propellers, pipelines, risers, and dam structures. This visual evidence helps identify corrosion, marine growth, and structural damage, providing a reliable record for inspection reports and classification society approvals. With advanced lighting, zoom, and pan-tilt functions, underwater cameras deliver clear visuals even in low visibility conditions, enabling accurate assessments and long-term monitoring of asset integrity. These inspections not only support preventive maintenance and repair planning but also serve as verifiable proof of compliance with international standards and regulatory requirements.

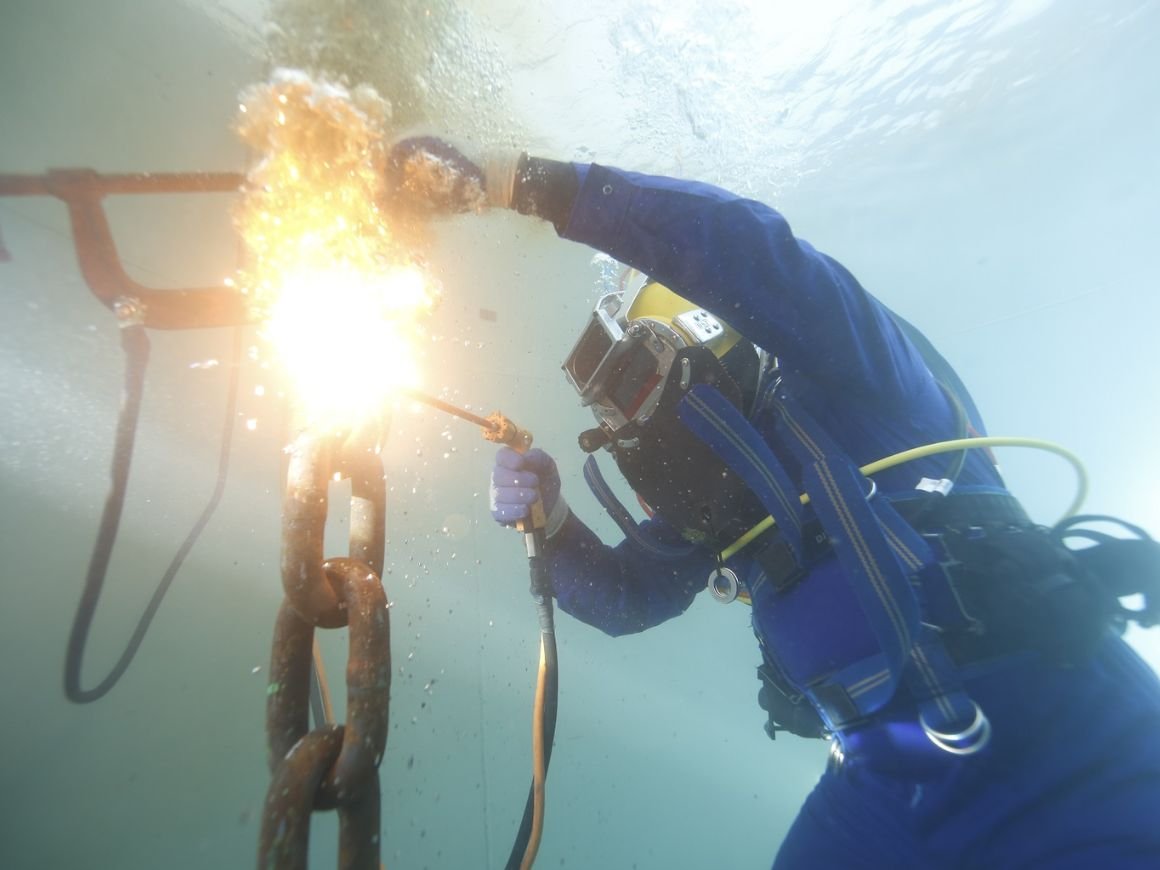

Underwater cutting and welding.

Underwater cutting and welding are specialized services used for the repair, modification, and maintenance of submerged structures such as ship hulls, offshore platforms, subsea pipelines, risers, and hydro power installations. These operations are carried out by certified commercial divers trained in wet welding and cutting techniques, using advanced equipment designed to function safely in underwater environments.Underwater welding, either wet welding directly in the water or hyperbaric welding in a pressurized chamber, is used to join or reinforce metal components, repair cracks, attach patches, or install clamps and anodes. These techniques are essential for emergency repairs and long-term asset integrity, reducing the need for costly dry-docking or dewatering. By combining diver expertise with class-approved welding procedures, underwater cutting and welding and durable solutions that extend the service life of critical marine and offshore assets.

Underwater Construction, Maintenance & Repairs of hydro power plants, dams, railway bridges, etc.

Underwater construction, maintenance, and repair services are vital for ensuring the safety, reliability, and long-term performance of critical infrastructure such as hydro power plants, dams, railway bridges, and other water-retaining or river-crossing structures. Continuous exposure to flowing water, high hydrostatic pressure, silt, debris, and corrosion causes deterioration of structural components, gates, piers, and foundations over time. Specialized commercial divers and ROVs, supported by advanced underwater equipment, carry out activities such as concrete and steel repairs, gate and groove refurbishment, sealing of leaks, debris removal, installation of protective coatings, welding, and cutting operations. These interventions are often performed without the need for full dewatering, reducing downtime and operational disruptions.

De-silting of Intake Canal, Pump House, Intake Chamber, etc.

De-silting of intake canals, pump houses, and intake chambers is an essential maintenance activity to ensure uninterrupted water flow for hydro power plants, irrigation systems, and industrial facilities. Over time, gravel, and debris carried by flowing water settle in these areas, reducing water capacity and causing excessive wear on pumps, turbines, and gates. If not addressed, sediment build-up can lead to reduced efficiency and unplanned shutdowns. De-silting operations are carried out using a combination of dredging equipment, high-capacity pumps, suction systems, and diver-assisted hydro-jetting to safely remove accumulated deposits. In confined or critical areas, specialized underwater tools and ROVs are also deployed to enhance precision. Regular de-silting not only restores the designed hydraulic capacity of intakes but also improves operational reliability, reduces maintenance costs, and extends the lifespan of water handling systems while ensuring compliance with environmental and safety regulations.

Underwater corrosion resistant Epoxy coating, Grouting, Reinforcing & Concreting.

Underwater corrosion-resistant epoxy coating, grouting, reinforcing, and concreting are specialized techniques used to protect and restore submerged structures such as dam walls, hydro power intakes, bridge piers, offshore platforms, and marine installations. To counter this, divers apply corrosion-resistant epoxy coatings that create a protective barrier on steel and concrete surfaces, extending their service life. Grouting is carried out to fill voids, cracks, and cavities in foundations or structures, restoring stability and preventing seepage. Reinforcing and concreting underwater involve the placement of steel reinforcements and specially designed anti-washout concrete mixes that can be laid and compacted underwater without segregation. These techniques are executed using diver-assisted methods, tremie pipes, or pumping systems to ensure precision and durability.

Annual & Periodic survey, maintenance & repairs of Hydro Power Plants, Dams and Irrigation channels.

Annual and periodic surveys, maintenance, and repairs of hydro power plants, dams, and irrigation channels are essential to ensure the safe, reliable, and efficient operation of these critical water management systems. Continuous exposure to water pressure, silt, debris, and environmental factors leads to gradual deterioration of gates, intake structures, canals, spillways, and other hydro-mechanical and civil components. Through scheduled surveys, divers and engineers carry out detailed inspections using visual, video, and non-destructive testing methods to identify corrosion, sedimentation, or structural wear. Based on findings, preventive and corrective maintenance is undertaken, including cleaning of intake channels, de-silting, seal replacement, coating applications, gate and groove repairs, and strengthening of concrete or steel elements. Periodic upkeep not only prevents unexpected failures but also extends asset life, improves efficiency, and ensures compliance with safety and regulatory standards.

De-silting of water reservoir, pipelines, etc and many more….

De-silting of water reservoirs, pipelines, and other water-retaining or conveyance systems is a critical activity to maintain their designed storage and flow capacity. Over time, fine particles, sand, silt, and organic matter carried by inflows settle in reservoirs and pipelines, reducing volume, obstructing flow, and increasing pressure losses. In addition, sediment build-up can accelerate corrosion, damage pumps and turbines, affect water quality, and compromise the efficiency of irrigation, power generation, and industrial supply systems. De-silting operations are carried out using dredging equipment, high-capacity pumps, suction systems, hydro-jetting, and diver-assisted removal methods, depending on the site conditions. These processes restore hydraulic efficiency, prevent blockages, and extend the operational life of reservoirs and distribution pipelines.