UNDERWATER MARINE CONSTRUCTION & DREDGING

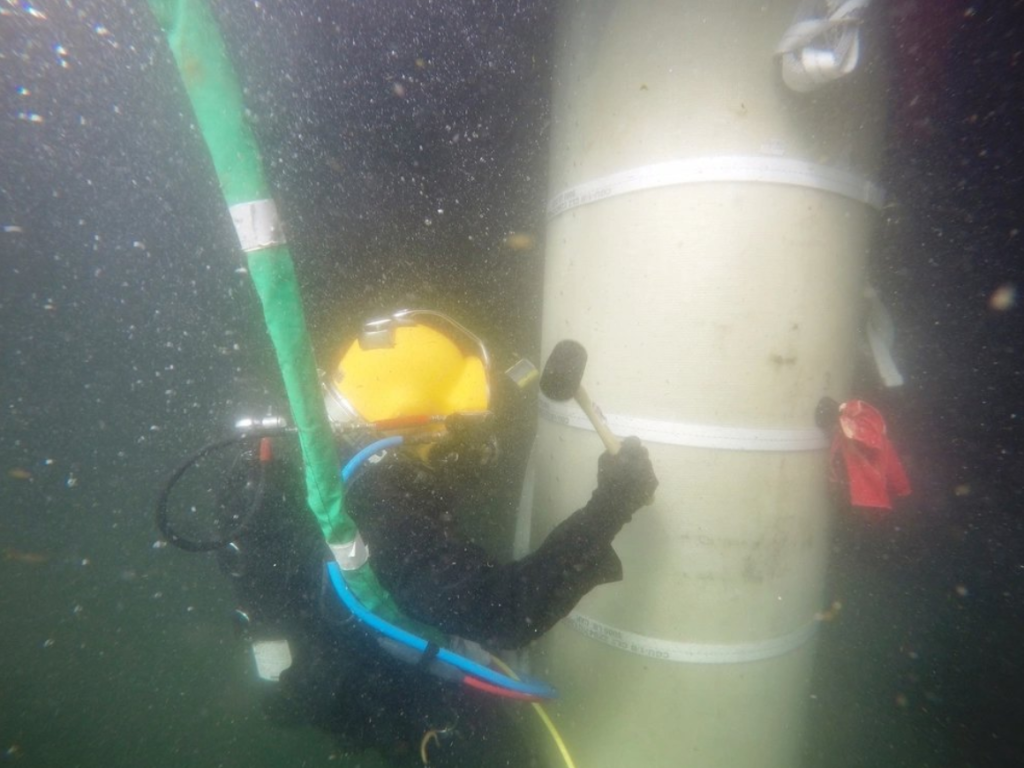

Underwater construction services.

Underwater construction services are specialized operations that involve building, installing, and modifying structures below the waterline for projects such as hydro power plants, dams, ports, bridges, offshore platforms, pipelines, and marine terminals. These services require highly skilled commercial divers, supported by advanced equipment like hydraulic tools, cutting and welding systems, ROVs, cofferdams, and heavy-lifting arrangements, to execute complex tasks safely and precisely in challenging underwater environments. Typical activities include installation of foundations, piling, concreting, reinforcing works, anode and coating applications, gate and groove construction, pipeline and riser installation, and subsea structural assembly. Underwater construction ensures that critical infrastructure is built or modified without the need for full dewatering or dry-docking, significantly reducing project downtime and costs.

Complete Engineering, Installation and Commissioning of Pipeline & Cable laying projects.

Complete engineering, installation, and commissioning of pipeline and cable laying projects involve end-to-end solutions that ensure reliable subsea and onshore connectivity for oil and water, and communication networks. These projects begin with engineering and pre-installation surveys, including route mapping, geotechnical and geophysical studies, and risk assessments to design the most efficient and secure alignment. The installation phase includes pipe and cable laying using barges or ROV-assisted burial systems, along with diver-supported tie-ins, clamps, stabilization with mattresses or grout bags, and protection against seabed movement. Specialized equipment such as tensioners and laying carousels ensure precise handling and placement. Finally, the commissioning stage involves hydrotesting, pigging, flushing, electrical and integrity testing, and system verification to confirm operational readiness and compliance with international standards.

Installation & Replacement of anodes, fenders, bumpers, shock observers, etc.

Installation and replacement of anodes, fenders, bumpers, and shock absorbers are essential underwater and marine maintenance services that protect critical assets such as ships, dams, hydro power plants, offshore platforms, ports, and jetties. Anodes are installed or replaced as part of cathodic protection systems to safeguard steel structures, pipelines, and vessels from corrosion, ensuring long-term durability. Fenders and bumpers serve as energy-absorbing barriers on docks, jetties, and vessel hulls, preventing impact damage during berthing and operations, while shock absorbers reduce vibrations, impact loads, and structural stress on gates, piers, and hydraulic equipment. Over time, these components wear out due to corrosion, abrasion, and mechanical stresses, requiring timely inspection, removal, and installation of new units using diver-assisted methods, hydraulic tools, welding, or heavy-lifting equipment.

Underwater Survey, Inspection and Maintenance of Pipelines.

Underwater survey, inspection, and maintenance of pipelines are essential to ensure the safe and long-term operation of subsea and underwater pipeline systems used in oil, gas, water, and industrial applications. These pipelines face constant threats from high pressure, saltwater corrosion, shifting seabeds and hydrodynamic forces, making regular monitoring and upkeep vital. Surveys are carried out using divers, ROVs, sonar mapping, and cathodic protection potential measurements to assess seabed conditions, burial depth, and external damage. Detailed inspections with CCTV, visual methods, and non-destructive testing techniques such as ultrasonic thickness measurement, MPI, and radiography help identify coating failures, wall thinning, and weld defects. Maintenance activities include marine growth removal through hydro-jetting, coating repairs, anode installation for corrosion protection, stabilization of free spans using grouting or mattressing, and leak repairs using clamps or welding. Internal cleaning through pigging and flushing further ensures flow efficiency.

Underwater Cutting & Welding of sheet piles, liners, reinforcement bars, Concrete etc.

Underwater cutting and welding of sheet piles, liners, reinforcement bars, and concrete structures are specialized services carried out to support the construction, strengthening, and repair of marine and hydraulic infrastructure such as dams, bridges, ports, offshore platforms, and retaining walls. These operations are performed by certified commercial divers using advanced underwater welding techniques—both wet welding directly in water and hyperbaric welding in controlled pressurized environments—to repair cracks, install reinforcements, or join steel components with durability and precision. Cutting operations, using oxy-arc, plasma arc, or hydraulic tools, are employed to remove damaged sections of sheet piles, trim reinforcement bars, or prepare concrete surfaces for repair and retrofitting.

Underwater welding of u/w structures, pipelines, etc.

Underwater welding of submerged structures and pipelines is a critical service used for the repair, strengthening, and installation of offshore and marine infrastructure such as subsea pipelines, risers, ship hulls, bridge piers, sheet piles, and hydro power installations. Performed by highly trained commercial divers, underwater welding is carried out using techniques like wet welding, where electrodes are used directly in the water, or hyperbaric welding, where a pressurized chamber creates a dry environment around the weld for superior quality. These methods enable the repair of cracks, joining of steel sections, reinforcement of corroded areas, and installation of clamps or brackets without the need for dry-docking or full dewatering. Weld integrity is verified through non-destructive testing to ensure strength, durability, and compliance with class and industry standards.

Construction, Repair & Maintenance of Jetties, Ports, Breakwater, Harbour, etc and many more...

Construction, repair, and maintenance of jetties, ports, breakwaters, harbours, and related marine infrastructure are essential services that ensure safe navigation, cargo handling, coastal protection, and long-term structural stability. These critical facilities are constantly exposed to harsh marine conditions including wave action, strong currents, corrosion, and sedimentation, which can cause structural wear, damage, and reduced operational efficiency. Specialized underwater and civil engineering techniques are employed for foundation construction, piling, concreting, reinforcement, installation of fenders and bumpers, as well as dredging and de-silting to maintain depth and accessibility. Repair and maintenance activities include underwater welding and cutting, coating and anode installation for corrosion protection, replacement of damaged components, and strengthening of piers, decks, and quay walls.

Construction & repairs of sea intakes and outfalls.

Construction and repair of sea intakes and outfalls are vital marine engineering services that ensure continuous and efficient water flow for power plants, desalination facilities, industrial cooling systems, and wastewater discharge networks. Sea intakes supply large volumes of seawater for cooling and process use, while outfalls safely return treated water back to the sea. Over time, these systems are exposed to harsh conditions such as corrosion, marine growth, siltation, structural wear, and storm damage, which can obstruct flow or compromise integrity. Construction activities involve surveying, trenching, laying intake or outfall pipelines, installing intake heads, and securing them with protective structures to prevent blockages and damage. Repair and maintenance include underwater inspection, reinforcement, welding, and replacement of damaged liners or structural components, often performed by divers and ROVs using specialized tools.

Gabion & Block placement under bridges and intake canals.

Gabion and block placement under bridges and intake canals is an important civil and underwater engineering activity designed to provide structural stability, erosion control, and scour protection in high-flow or sediment-heavy environments. Bridges, intake canals, and hydraulic structures are constantly subjected to strong currents, turbulence, and sediment movement, which can erode foundations, undermine piers, and compromise long-term safety. To mitigate these risks, gabions (wire mesh cages filled with stones) and concrete blocks are strategically placed underwater to stabilize soil, protect foundations, and dissipate hydraulic energy. Divers and specialized equipment ensure accurate positioning and compaction of these protective units, even in areas with low visibility and strong currents.

Underwater services for rock blasting and well sinking.

Gabion and block placement under bridges and intake canals is an important civil and underwater engineering activity designed to provide structural stability, erosion control, and scour protection in high-flow or sediment-heavy environments. Bridges, intake canals, and hydraulic structures are constantly subjected to strong currents, turbulence, and sediment movement, which can erode foundations, undermine piers, and compromise long-term safety. To mitigate these risks, gabions (wire mesh cages filled with stones) and concrete blocks are strategically placed underwater to stabilize soil, protect foundations, and dissipate hydraulic energy. Divers and specialized equipment ensure accurate positioning and compaction of these protective units, even in areas with low visibility and strong currents.

Underwater corrosion resistant Epoxy coating, Grouting, Reinforcing & Concreting.

Underwater corrosion-resistant epoxy coating, grouting, reinforcing, and concreting are specialized techniques used to protect, repair, and strengthen submerged structures such as dams, hydro power plants, bridges, ports, and offshore platforms. Constant exposure to water, salt, and aggressive environmental conditions accelerates corrosion of steel and deterioration of concrete, compromising structural integrity. To counter this, divers apply epoxy coatings that create a durable protective barrier against corrosion, while grouting is used to fill cracks, voids, and cavities in foundations and structural members to restore stability and prevent seepage. Reinforcing and concreting works involve the placement of steel reinforcements and specially designed anti-washout concrete mixes that can be placed underwater without segregation, ensuring long-lasting strength and bonding.

Pressure pointing & grouting.

Pressure pointing and grouting are essential underwater and civil engineering techniques used to repair, seal, and strengthen structures such as dams, hydro power plants, bridges, tunnels, and retaining walls that are exposed to constant water pressure and seepage. Pressure pointing involves the application of specialized mortar under pressure into joints, cracks, or deteriorated masonry to restore watertightness and improve bonding strength, particularly in stone or brick structures. Grouting, on the other hand, uses cementitious, chemical, or epoxy-based materials injected under controlled pressure into voids, cavities, and fractures within concrete or rock foundations to enhance stability, reduce permeability, and prevent water ingress. When performed underwater or in high-pressure environments, these techniques are executed using diver-assisted equipment, pumping systems, and monitoring tools to ensure precision and durability.

Dredging in Navigational Channel.

Dredging in navigational channels is a vital marine service that ensures safe and efficient vessel movement by maintaining the required depth, width, and alignment of waterways. Over time, channels accumulate silt, sand, sediments, and debris due to tidal action, river inflows, and storms, which reduce draft depth, restrict navigation, and increase the risk of vessel grounding. Through mechanical, hydraulic, or diver-assisted dredging methods, these deposits are carefully removed to restore channel capacity and improve navigability. The process typically involves hydrographic surveys, deployment of specialized dredgers, sediment removal, transport to disposal or reclamation sites, and post-dredging inspections to confirm compliance with navigational requirements.

Port & Harbour maintenance etc and many more….

Port and harbour maintenance is a critical service that ensures the smooth, safe, and efficient functioning of maritime infrastructure that supports global trade, transportation, and coastal activities. Continuous exposure to tides, waves, siltation, corrosion, and heavy vessel traffic leads to gradual deterioration of berths, quay walls, fenders, navigational channels, and other port assets. Maintenance activities include dredging to maintain draft depth, inspection and repair of quay and jetty structures, replacement of fenders and bumpers, underwater welding and coating for corrosion protection, and cleaning or de-silting of intake and drainage systems. Regular inspection with divers and advanced monitoring technologies ensures early detection of structural issues, allowing timely repairs to prevent costly breakdowns or disruptions. By combining underwater engineering, civil works, and preventive maintenance programs, port and harbour services safeguard infrastructure reliability, extend service life, and maintain compliance with international marine safety standards.